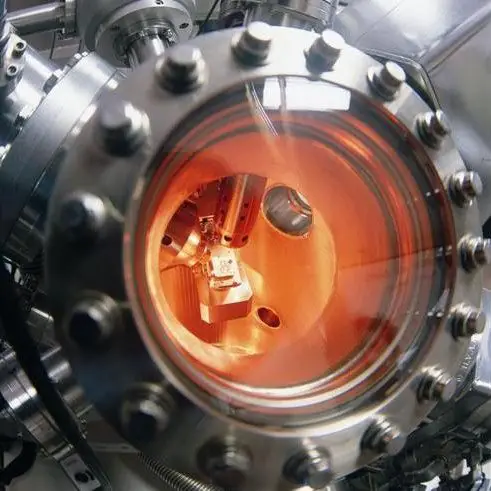

Materials Laboratory & Services for the Electronics Industries

Surfaces Characterization

Often the surface characteristics of a material significantly affect its performance from different points of view: solderability, adhesion, wettability, cleaning…

Often the surface characteristics of a material significantly affect its performance from different points of view: solderability, adhesion, wettability, cleaning…

Their equipment allows them to characterize a surface from both chemical and morphological point of view, giving the customer a valid help for the setting up of processes and for the solution of problems.

Qualification / Validation of Materials and Processes

PIEK’s Partner performs failure analyses combining mechanical, electrical, chemical and metallographic techniques. Thanks to the experience of their IPC certified analysts, they offer consultancy on assembly process and materials’ quality in the electronic field.

PIEK’s Partner performs failure analyses combining mechanical, electrical, chemical and metallographic techniques. Thanks to the experience of their IPC certified analysts, they offer consultancy on assembly process and materials’ quality in the electronic field.

Chemical Laboratory

The chemical laboratory is equipped with a complete set of analytical techniques, from elementary analysis to thermal analysis, from chromatography to infra-red spectroscopy and UV-visible. This allows us to offer a wide range of services and analysis in several areas, including: characterization of polymers, identification of contaminated (ionic and non), analysis of metal alloys… Moreover, our engineers are available to develop specific tests to meet the needs of the customer.

The chemical laboratory is equipped with a complete set of analytical techniques, from elementary analysis to thermal analysis, from chromatography to infra-red spectroscopy and UV-visible. This allows us to offer a wide range of services and analysis in several areas, including: characterization of polymers, identification of contaminated (ionic and non), analysis of metal alloys… Moreover, our engineers are available to develop specific tests to meet the needs of the customer.

Failure Analysis

Passive and active electronic component failure analysis:

Passive and active electronic component failure analysis:

– Electrical test

– Constructive analysis

– Electronic application review and validation

Electronic Design assemblies failure analysis:

– Root cause determination

– Component stress evaluation

– Design validation

Compliance with RoHS Directive and Environmental Analysis

PIEK’s Partner aims to offer its customers a comprehensive service concerning the RoHS Directive, both for the materials’ analysis and for documentation management.

PIEK’s Partner aims to offer its customers a comprehensive service concerning the RoHS Directive, both for the materials’ analysis and for documentation management.

In fact, their laboratory makes available its competences to help the customer position its product against the standard, manage the collection of conformity certificates and, eventually, proceed with the chemical analysis of materials, both at the screening level (by XRF spectroscopy) and at more accurate determination, all according to the method IEC 62321.

In addition, since January 2013 the RoHS compliance is a requirement of CE Mark and PIEK’s Partner, thanks to the collaboration with a laboratory partner, is able to provide its customers the support about all directives provided from this certification.

Other environmental analysis

The laboratory can determine the concentration of asbestos in air, in accordance to DM 6/9/94 by electronic microscopy (SEM/EDX).

Statistical Analysis of Product Design, Process and Reliability

The main services provided are:

The main services provided are:

- FMEA of project and process (also according to the Automotive standard).

- Statistical analysis of processes: ANOVA (evaluations of factors affecting the process), statistical tests (comparison between different samples and processes), sampling plans (evaluation of defectiveness in a lot or a process), DOE (optimization of process’ parameters).

- Measurement System Analysis (MSA) for attributes and variables, calculation of repeatability, reproducibility, measurement uncertainty, accuracy (also according to the Automotive standard).

- Reliability analysis: MTBF, IFR, time evolution of reliability parameters, evaluation of acceleration factors.

Shock and Vibration

Dynamic tests can be performed to assess finished products and subassemblies solidity and reliability, with or without packaging.

Dynamic tests can be performed to assess finished products and subassemblies solidity and reliability, with or without packaging.

Tests (in compliance with international standards or with customer’s requirements) can be applied not only on electronic applications, but also on other industrial fields: military, telecommunication, medical, household appliances, alimentary…

Dimensional Analysis

PIEK’s Partner metrological area has equipment that can measure, with extremely high precision, dimensions of electronic and mechanical components, under controlled environmental conditions.

PIEK’s Partner metrological area has equipment that can measure, with extremely high precision, dimensions of electronic and mechanical components, under controlled environmental conditions.

Reliability Analysis for Processes and Products

Aim of these analyses is to guarantee that products meet specifications in terms of functionality and lifetime.

Aim of these analyses is to guarantee that products meet specifications in terms of functionality and lifetime.

PIEK’s Partners thermal and environmental chambers and electronic equipment allow monitoring and verifying reliability of processes and products according to international standards or customer’s requirements.

ESD Measures (ElectroStatic Discharge)

Conductivity measurements on materials and their classification:

Conductivity measurements on materials and their classification:

– Pavement, work tables’ surfaces, cabinets,…

– Packaging (envelopes, cardboard, fillers,…)- EPA (ESD Protected Area) Conformity Assessment with current standards

- Analysis of individual protection (ESD armbands, shoes, lab coats,…)

Rework and Repair Processes for Microelectronics

Rework clinic of high technological capability:

Rework clinic of high technological capability:

– BGA Reballing

– BGA Rework

– PCB repair, assembled and not

– Circuit boards with “High Thermal Mass”

Counterfeiting of Electronic Components

In the last years, the problem of counterfeit components is spreading more and more in the electronic field.

In the last years, the problem of counterfeit components is spreading more and more in the electronic field.

To respond to market demands, PIEK’s Partners laboratory has developed a number of tests to verify the legitimacy of suspect components.

| Service | Test Method |

|---|---|

| Cross-sectioning | ASTM E3/IPC-TM650 2.1.1 |

| Manufacturing Handling Simulation (Dye & Pry testing) | |

| Solder float test (Thermal stress , plated-through holes) | IPC TM650 2.6.8 |

| Solder float test (Thermal stress of laminates) | IPC TM650 2.4.13.1 |

| Solderability test for components and/or PCB | J-STD-002 J-STD-003 |

| X-ray Fluorescence (XRF thickness) | ASTM B568 (98) (Reapproved 09) ISO 497 |

| X-ray Photoelectron Spectroscopy (XPS) | ASTM E1078-90, E1015-90, E902-88, E673-90 |

| Atomic Force Microscopy (AFM) | |

| Scanning Electron Microscopy (SEM w/EDX) | |

| Instron testing (mechanical Pull strength test) | IEC 62137-1-1 |

| Instron testing (mechanical Shear strength test) | IEC 62137-1-2 |

| Fourier Transform Infrared Spettroscopy (FTIR) on pure compounds | ASTM E 1252 |

| Fourier Transform Infrared Spettroscopy (FTIR) on residues | ASTM E 1252 |

| Fourier Transform Infrared Spettroscopy (FTIR) on residues with research on spectra library | ASTM E 1252 |

| Ion Chromatography (7 anions) | IPC TM 650 2.3.28B |

| Total Ionic Contamination | IPC TM 650 2.3.25.1 |

| Total Ionic Contamination by OMEGAMETER 600 | IPC TM 650 2.3.25D |

| Metallic alloy by ICP-AES | Internal methods |

| Porosity test | ASTM B 735 |

| Contact angle meter | ASTM D 5725-99 (2008) |

| Tg and CTE determination by TMA | IPC TM 650 2.4.24C |

| Time to delamination by TMA | IPC TM 650 2.4.24.1 |

| Tg determination by DSC | IPC TM 650 2.4.25C |

| Tg determination by DMTA | IPC TM 650 2.4.24.2 |

| TGA analysis | ASTM E 1131 |

| Acid value | IPC TM 650 2.3.13A |

| Solid content, flux in liquid flux | IPC TM 650 2.3.34C |

| Solid content, flux in solder paste and/or cored wires | IPC TM 650 2.3.34C |

| Metal content | IPC TM 650 2.2.20 |

| Melting point | ASTM E794-89 |

| Copper mirror test | IPC TM 650 2.3.32D |

| Bromide and Chloride content | IPC TM 650 2.3.28.1 |

| Halide Content, Quantitative (Chloride & Bromide) | IPC TM 650 2.3.35C |

| Solder Powder Particle Size Distribution-Measuring microscope Method | IPC TM 650 2.2.14.1 |

| Corrosion test | IPC TM 650 2.6.15C |

| Peel Strength of Metallic Clad Laminates | IPC TM 650 2.4.8C |

| Solder Mask Abrasion (Pencil Method) | IPC TM 650 2.4.27.2A |

| Adhesion, Solder Mask | IPC TM 650 2.4.1E (tape test) |

| Solder paste – Slump Test | IPC TM 650 2.4.35 |

| Decomposition Temperature (Td) of Laminate Material Using TGA | IPC TM 650 2.4.24.6 |

| Solder Paste – Solder Ball Test | IPC TM 650 2.4.43 |

| Solder Paste – Wetting Test | IPC TM 650 2.4.45 |

| Solder paste rheology | Internal methods |

| Gel time – room temperature | Internal methods |

| Gel time – temperature requested by customer | Internal methods |

| Carbon and sulphur determination by LECO CS-244 (infrared detection) | ASTM E1019 |

| Determinazione Assorbimento H2O nei polimeri | ASTM D570 |

| S.I.R. Test | IPC TM650 2.6.3.3B |

| Resistance to Electrochemical Migration, Solder Mask | IPC TM650 2.6.14D |

| Electrochemical Migration Resistance Test | IPC TM650 2.6.14.1 |

| Shock test system | |

| SAM (Scanning Acoustic Microscopy) | |

| X-ray analysis (FEIN FOCUS) | |

| X-ray Tomography analysis | |

| Chamber Services | |

| Shock test system | |

| Vibration test system | |

| Dimensional analysis by contact or optical machine | |

| Optical Dimensional verification (on PCB) | IPC TM650 2.2.2B |

| Bow & Twist measurement (on PCB) | IPC TM 650 2.4.22C |

| Mechanical Dimensional Verification (on PCB) | IPC TM 650 2.2.1A |

| Surface Roughness and profile of Metallic Foils (Contacting Stylus Technique) (on PCB/Cards) | IPC TM 650 2.2.17A |

| Roughness by contact profilometer | UNI EN ISO 4288 (2000) / UNI EN ISO 4287 (2002) |

| MTBF Test (Mean time between failures) | |

– RoHS analysis Service |

Test Method |

| Sample preparation (to separate samples in homogeneous materials) | |

| 1 chemical element by ICP-AES (in homogeneous sample) | |

| 4 chemical el (Pb/Hg/Cd/Crtot) by ICP-AES (in hom sample) | IEC 62321 |

| Determination of Cr VI by EN ISO 3613:2001 (in hom. Sample) | IEC 62322 |

| Determination of Cr VI by UV-VIS (in hom. Sample) |

Please contact our sales department if you are interested in our Test Center activities. We will be happy to provide more information about our testing services.