Solder Training Basic (Hand Soldering)

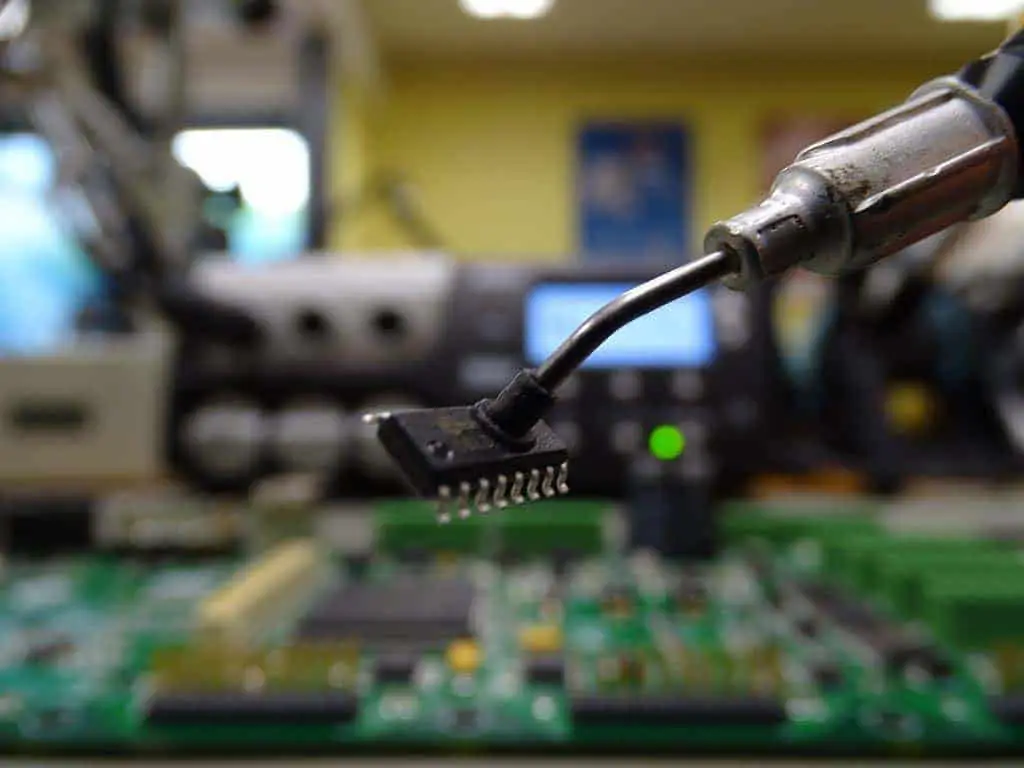

In the Solder Training Basic (Hand Soldering), we discuss hand soldering in theory and in practice. It starts with a piece of theory in which what is soldering, what happens during soldering, what is a soldering connection, what materials do you connect with each other and what connection materials do you use, are discussed.

Important knowledge that someone needs to understand so that he knows what he is doing while hand soldering. It is often a problem that people solder and know how to operate a soldering iron, but do not really know “what happens”. This is explained in theory and issues such as thermal energy and inter-metallic layers are discussed. Furthermore, this is also put into practice and solder connections are made. We start simple and gradually it is made a little harder. So that ultimately everyone who is interested in hand soldering, has a feeling for it and can understand it and continues to improve himself.

Soldering

Basic Hand Soldering course is suitable for the following target group:

In principle, the solder training course is suitable for anyone who performs soldering work or has to learn to perform it. Employees who have no experience yet, who have little experience and who want to learn hand soldering or have to expand their hand soldering knowledge in order to do their work properly. Because the theory is also discussed, it is actually interesting for anyone who may have been soldering for a while but who has never really had a good hand soldering course. Someone who has taught himself in practice but has not mastered the intricacies of hand soldering.

The Basic Hand Soldering Course is interesting for employees of different companies.

The basic course of hand soldering is interesting for companies where manual soldering takes place. Companies where people make solder connections by hand, where people do this during the soldering process, but also during the so-called rework processes. A repair process where components are replaced at a given moment that are already soldered in an automatic process. Or employees who work in the so-called repair departments. So not only companies that produce, but also perform rework and repairs. The course is therefore interesting for companies that employ people who carry out this type of hand soldering work.

PIEK: Your knowledge provider for the electronics industry

The added value of the Basic Hand Soldering Course.

The added value is that employees learn what they really do during the course. For Example: What happens now? What am I doing? The intention is to make employees aware that they can do a lot of things wrong, especially in the hand soldering process.

The aim of the course is therefore that people no longer make the mistakes they have made in the past. Or employees who start new with hand soldering to learn it well, so that they will not make mistakes in the future. So for the company the added value lies in the fact that employees make fewer mistakes, that they are more confident of what they are doing and that it can therefore be assumed that there will be less outages, less waste and that profit will increase because the costs are reduced.