Certified PIEK Operator – Quality criteria for soldered electrical and electronic assemblies

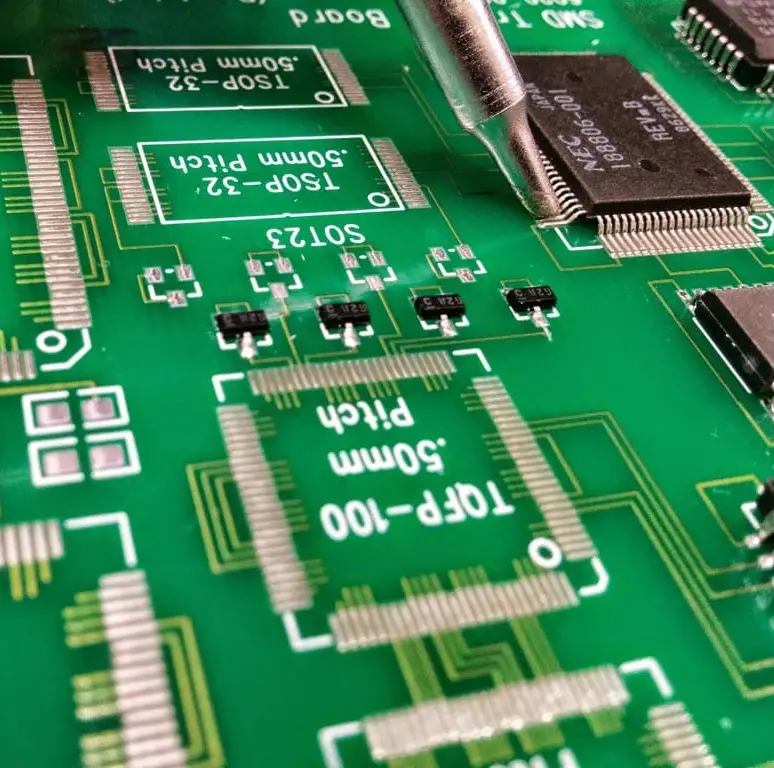

The Certified PIEK Operator – Quality criteria for soldered electrical and electronic assemblies training is a training course where the aspects of the soldering processes on electrical and electronic circuit boards are discussed.

So topics like tools, materials and also the criteria, the quality requirements that these products must meet.

The target group for this training is actually everyone who works in an assembly company and is somehow involved with soldering on electronic circuit boards, or in other words where solder connections are made on electronic products.

So this could be people who control the production processes or set them up or people who work in the quality department, in the soldering departments, where the actual soldering is carried out either automatically or by hand. Everyone who works in an electronics assembly company will benefit from this training.

PB Assembly

The Certified PIEK Operator – Quality criteria for soldered electrical and electronic assemblies training is suitable for the following target group:

In general this training is performed for electronics assembly companies that can immediately use this in their assembly process, but also for companies that built the end products. Quality departments of the so-called OEMs and EMS companies participate as well.

What you learn in particular in this training is which tools are generally used and how to handle them correctly. Furthermore specific information regarding the materials used, like fluxes, solder that is the different solder alloys that are used and how to select the proper one and why certain materials should or should not be used for certain products.

Also an important part of this training are the quality and acceptance criteria. So what is valid for the end product and the solder joints. Or in other words: what does a good solder joint look like, what are the criteria for solder joint anomalies.

What is allowed and what is not allowed? What does or does not affect the quality of the end product? This will also be discussed and the trainer will then deepen the information so the participants who been in this training will be able to take the correct decisions on the quality of the soldered connections. Furthermore, this training also discusses cleaning, cleaning aspects, cleanliness tests, so you will be able to judge if a product has been sufficiently and properly cleaned.

Adhesives are discussed as well as coating processes of the end product. And other issues that are important for the proper functioning of the end product, so any quality criteria that would apply.

The Certified PIEK Operator – Quality criteria for soldered electrical and electronic assemblies training is interesting for employees of different companies.

If you have followed this training, you will be able to assess all aspects of soldering processes on electrical and electronic circuit boards.

You will be able to make the right choice with regard to tools, the materials to use and also to decide whether the product meets those quality and acceptance requirements before delivering it to a customer.

But if on the other hand you work at the company that processes the assemblies then it would be good if you would be able to decide whether the products delivered meet the quality requirements and you can process them in your final product.

PIEK: Your knowledge provider for the electronics industry

PB Assembly

The added value of the Certified PIEK Operator – Quality criteria for soldered electrical and electronic assemblies training and certification.

The added value of this training is that participants get more secure, more confident, because they have learnt to use the criteria the correct way and are able to judge the products, the assemblies in the right way.

They can decide if the tools and materials that are used are correct and thus avoid mistakes, avoid quality problems which of course has an immediate impact on the financial loss and that too is added value of this training.

Apart from of course the certainty that you have learnt to properly assess the solder joints.