QRRE – Qualified Rework and Repair Engineer

training and certification

This is a training that mainly consists of practice. It is a PIEK own training that we have developed to meet the demands of our customers.

Because it is important for many companies that the staff learns how to replace components and to repair PCBs in the right way and without incorporating too much unnecessary theory.

The designation Qualified means that people are qualified and therefore must be able to perform their work properly at the end of the training.

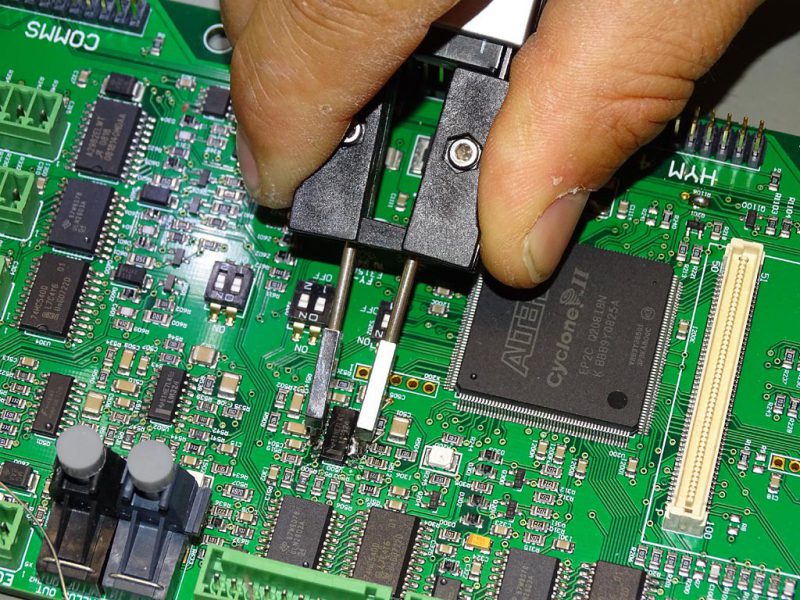

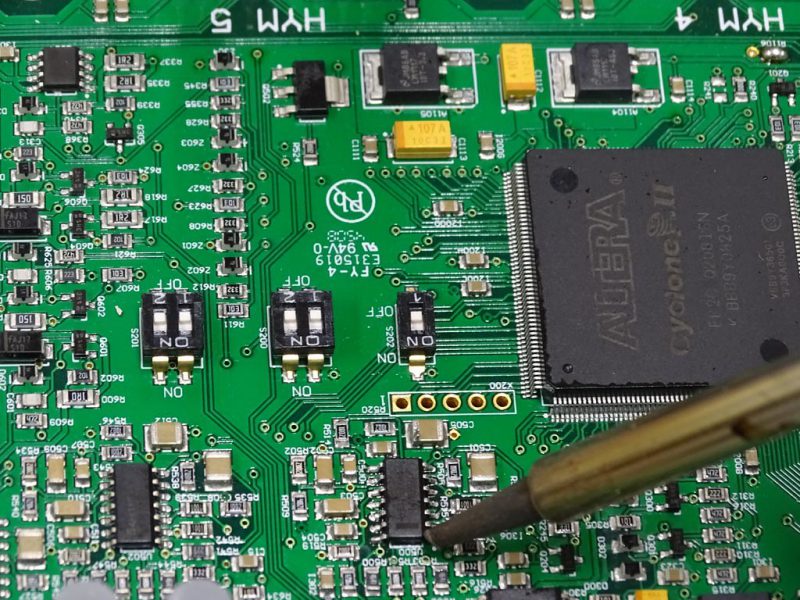

Rework and repair, these are operations that are performed and learned during the training. Rework means replacing components and improving solder connections to components if there is too little solder or whether that solder connection does not meet the requirements.

During repair, conductors are repaired, islands are repaired and possibly also printed circuit boards are repaired. Engineer, that means that someone is qualified as such.

What is very important in this training is learning to perform such actions in the right way. We limit ourselves to just the necessary theory.

What should someone know about a soldered connection? What is soldering? What happens during soldering? What could possibly go wrong with soldering? How is that solder connection structured? Why, if that solder connection is good, should you not do anything about it?

These are questions that are answered during this training and furthermore it is primarily a matter of practice. The trainer shows how different actions must be performed. The students then go to work themselves, practice and must also prove that in practice.

On the basis of a practical exam, built up during the course where the students can show what they have learned.

That concerns the rework part so the replacement of components. The removal of components, the preparation of the islets of new components and the replacement of new components are also exercises that are practised.

Furthermore, repairs are dealt with, in particular the repair of tracks, the repair of released or disappeared islands. Here too it is learned to replace it in the right, responsible way.

Moreover, in this training we also discuss a bit of modification. Changing a circuit with the help of a modification wire. This is explained in theory and practiced in practice and where a student must show that he has mastered it.

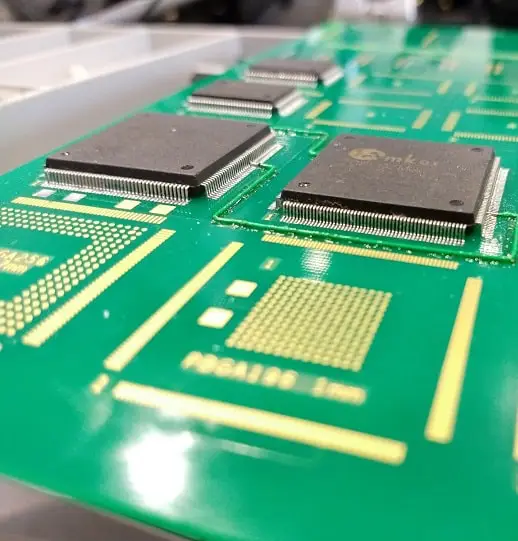

PB Repair and Rework

The QRRE – Qualified Rework and Repair Engineer training and certification is important for the following target group:

This training is important for people who are actually deployed in the companies for rework operations, for repair operations.

People who work in the repair departments, such as assemblers, EMS companies that produce electronics and the products that have fallen out, want to repair them again or possibly for companies that carry out repairs on order and customers have sent products back and they have to perform such repairs and rework assignments.

These are all practical acts. That is something that you must be taught, that you must practice and that you can implement in practice thereafter.

The QRRE – Qualified Rework and Repair Engineer training and certification is interesting for employees of different companies.

The companies that opt for this training are mainly companies that assemble electronics and as a service provider, produce electronic products for their clients.

Companies that have a department within their production department where rework and repairs are carried out and who want their staff to be trained in this field. Or repair companies that do so on behalf of their customers because the returned products have fallen out and have to be made functional again.

This training is in particular often carried out at companies that at some point primarily want their people to learn the practical skills without too much theoretical ballast.

PIEK: Your knowledge provider for the electronics industry

PB Repair and Rework

Application of the QRRE – Qualified Rework and Repair Engineer within companies.

If you have successfully completed this training, then you have learned how to correctly perform various repair and rework repairs.

A trainer has shown you, you have been able to practice and you had to show that you have mastered these skills in a practical exam.

So, after completing the training you can immediately put these skills into practice at your workplace.

Furthermore, you have learned what happens during soldering, what a solder connection is, what metallurgical aspects of that solder connection are, and so you can at some point start working more confidently within the rework and repair department where you work.

The added value of the QRRE – Qualified Rework and Repair Engineer training and certification.

The added value for a company to let employees participate in this QRRE Qualified Rework and Repair Engineer training lies in the fact that people learn how to desolder, solder, replace components and perform repairs properly. As prescribed in the various standards that are available for repair and rework. For many people the theoretical part is difficult and an unnecessary ballast.

This training is primarily a practical training with only the necessary theory. This means that people are immediately hands-on taught which is important for their daily work and can deploy it immediately afterwards. Someone who has followed this training will then immediately show results in daily practice and the staff is more accurate when carrying out the practical assignments that occur daily. As a result, there will be less downtime at some point and that is of course good for the company because the costs will go down and the return will go up.