Selective soldering has been on the rise in recent years. Sometimes the selective soldering system completely replaces the wave solder machine.

Ersa-ECOSELECT-1

More and more we see that 80% or even more of the components used are SMD-components. This means that less than 20% of the components used are the traditional through-hole components. This is especially the case with connectors and high-power components. Because of the miniaturisation of our SMD-components, the component density on circuit boards is getting higher as well. Using wave soldering processes to solder these kinds of components becomes almost impossible. The solution to this problem is the use of selective wave solder machines.

These improved and faster selective solder machines, often with multiple heads, are therefore indispensable in the current soldering processes.

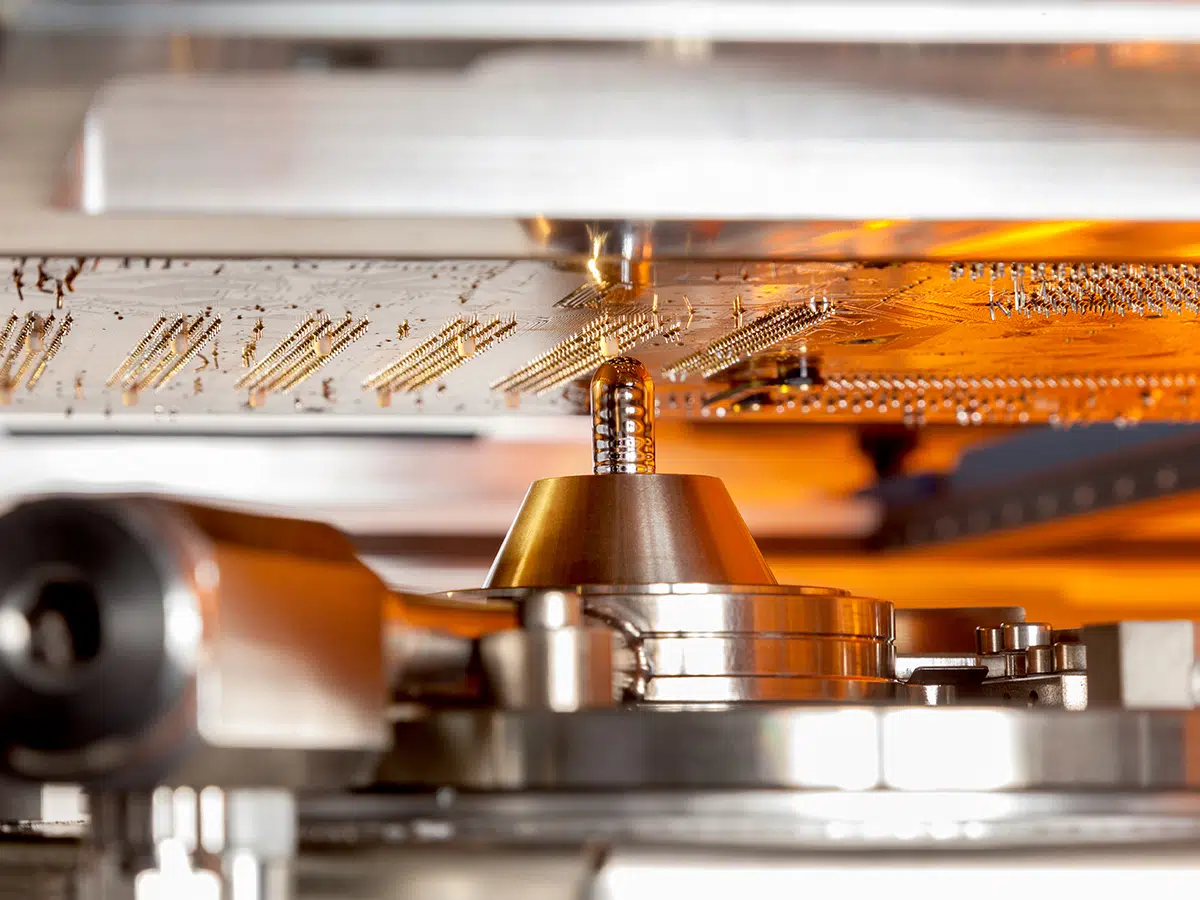

Solder module with multiple heads

A selective solder machine uses a small selective wave that moves in X-Y-Z directions under the circuit board (PCB) to the through-hole components to be soldered. If larger quantities through-hole components are to be installed on the PCB, one could use a machine with multiple selective heads to avoid issues with throughput speed.

Process tunnel with flux system

In the selective soldering process flux is used as well. First the flux is applied with a moving spray fluxer on the component leads, annular ring, and hole wall. Then the component and the PCB are preheated, and finally the selective solder wave solders the component.

Important parameters with the selective soldering process are: component lead length, selecting the proper solder-nozzle, the type of flux that is used and nitrogen. Nitrogen is used to avoid oxidation and to decrease the formation of dross.

“Peel-Off” function to help reduce bridging

Design for manufacturing (DFM) is important with selective soldering. Quite often the selective soldering process leads to problems and defects because in the design the SMD-pads are placed too close to the through-hole lands and there is insufficient space between solder wave and SMD-component.

Alternative methods to solder (through-hole) components in a selective manner are for instance laser soldering, mini-flame soldering and robotic solder systems. The latter might be equipped with a robot controlled soldering iron and solder wire.

All pictures copyright Ersa GmbH

We would like to thank Ersa GmbH for the use of the pictures in this article