A focus on the IPC-A-610 and IPC J-STD-001

Why this article?

The IPC-A-610 and the IPC J-STD-001 are complementary standards, but each has its own purpose. However, it is not always clear to everyone what the specific uses of both documents are.

What is the purpose and impact of the IPC-A-610?

The IPC-A-610 Acceptability of Electronic Assemblies is a standard for visual acceptance. What’s the meaning of this? That this is a document intended to be used as a guideline in the visual inspection of assembled electronics. In a company that assembles electronics, it is common that visual inspection take place before a product is sent to a customer. This is to prevent products being sent to a customer that do not meet the requirements.

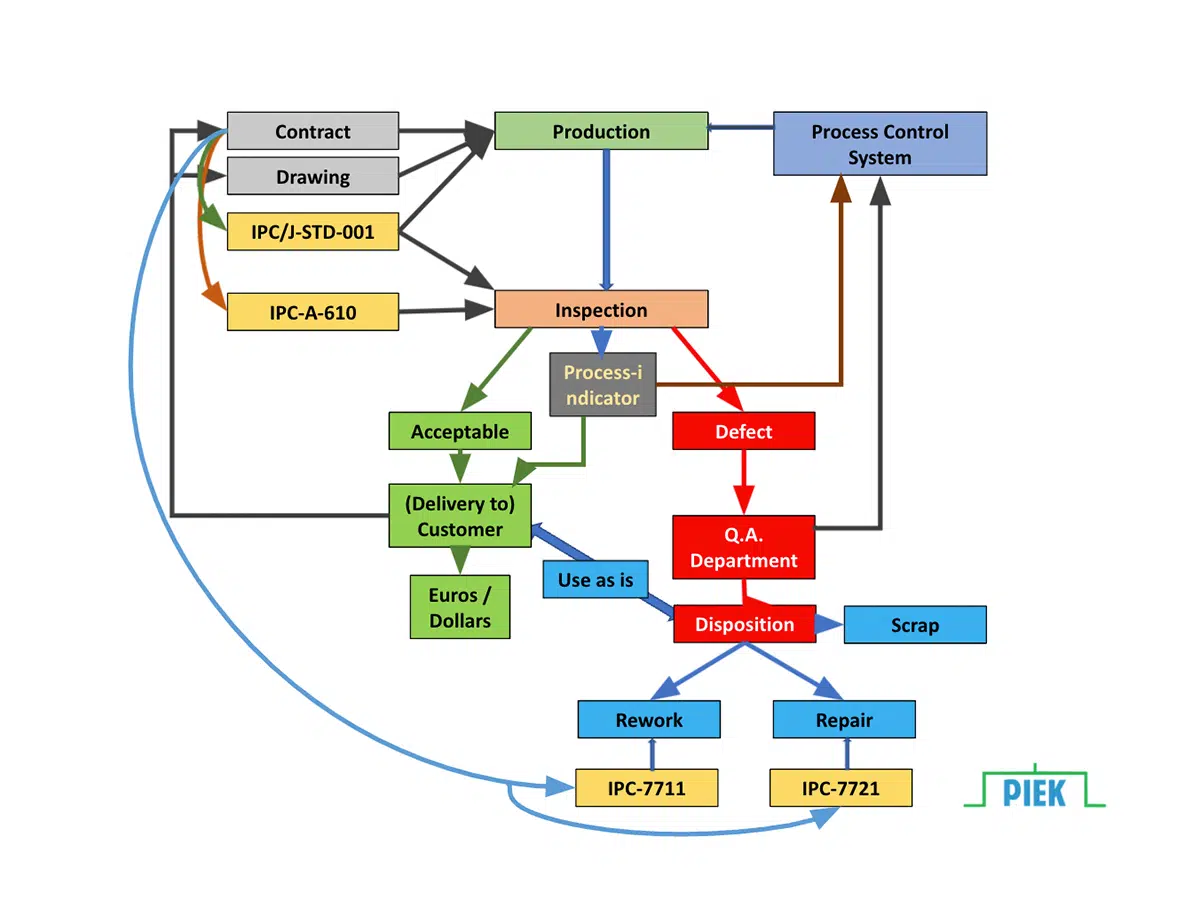

If a customer indicates in the procurement documentation that his product must be inspected in accordance with IPC-A-610, the inspector must inspect, check and compare the produced product with the requirements of the directive. Only the products that comply may be sent to the customer. Rejected products may be processed so that they still meet the requirements, but may also be scrapped, depending on the applicable regulations.

To assist the inspector (and other users of the IPC-A-610) in the interpretation of the written requirements, this document contains hundreds of images. This way the user can get a good idea of what is described in the texts.

The user of this guideline (inspector) will especially feel helped by the certainty that he approves or rejects products on the basis of the texts and images. As a company, this gives me the assurance that my delivered products meet the requirements of my customer. A customer who knows the contents of the IPC-A-610 and its impact on his product can rest assured that he will receive products that meet his requirements.

What is the purpose and impact of the IPC J-STD-001?

The IPC J-STD-001, Requirements for Soldered Electrical and Electronic Assemblies is a material and process specification guideline and provides a lot of written information with a limited number of illustrations. The approach here is that users of this guideline will mainly be people who are properly trained in the usual soldering processes or who have sufficient experience in this. This includes process engineering employees.

Do not expect photos or drawings for every paragraph in this document. The text is deliberately kept compact and written in such a way that one should be properly prepared to deal with it. For example, requirements are explained, but how these can be interpreted for the three product classes is indicated with codes. It is therefore important that people know how to deal with this in the right way, a thorough training is absolutely necessary.

The structure and structure of the document is such that one builds on process control, ISO 9001 or similar is therefore necessary if one wants to implement this document in a company. Since this is a process document, it covers the materials that may be used and also the tools and equipment. Attention is also paid to requirements for the working environment such as temperature and humidity. The documentation that is necessary and that could be checked by a customer in the event of a possible audit by a customer is also discussed in detail. In addition to deviations from the product, deviations in the process are also discussed.

What is the benefit to me as a company if I implement both standards?

Despite the overlap between the two documents, each guideline has its specific application. By implementing both documents in a company, I get a grip on both the production processes and the inspection of the finished product. The structure of both documents is such that each user group can make optimal use of the information provided. Process engineers find the necessary process information in the IPC J-STD-001, inspectors are helped by the images in the IPC-A610.

Since both documents are complementary, there is a common language within the company and it is easier to communicate with each other. And also improve external communication flows because people can also speak the same language with customers and suppliers. International language barriers disappear because the translations also follow the standardized structure.

With the IPC-A-610 I gain insight and control over the quality of my product. The IPC J-STD-001 also gives me process assurance, the assurance that I have performed the soldering processes correctly and that all applicable documents have been used.

If you want to implement both documents in your company, consider that, to indeed speak of complementarity, both documents have the same revision status, so for example IPC-A-610H together with J-STD-001H.