Measuring is Knowing. Guessing is Missing. Measure the temperature profiles and other variables of your reflowsoldering, wavesoldering, vapour-phase-soldering- and rework & repair processes.

This can be accomplished quite easily with the Smart Profiler SuperM.O.L.E.® Gold 2 from ECD or another datalogger.

Still too often I see in many electronics companies operators repairing defects on printed circuit board assemblies (PCBA) after the reflow-, wave soldering or vapour phase process.

Still too often I see in many electronics companies operators repairing defects on printed circuit board assemblies (PCBA) after the reflow-, wave soldering or vapour phase process.

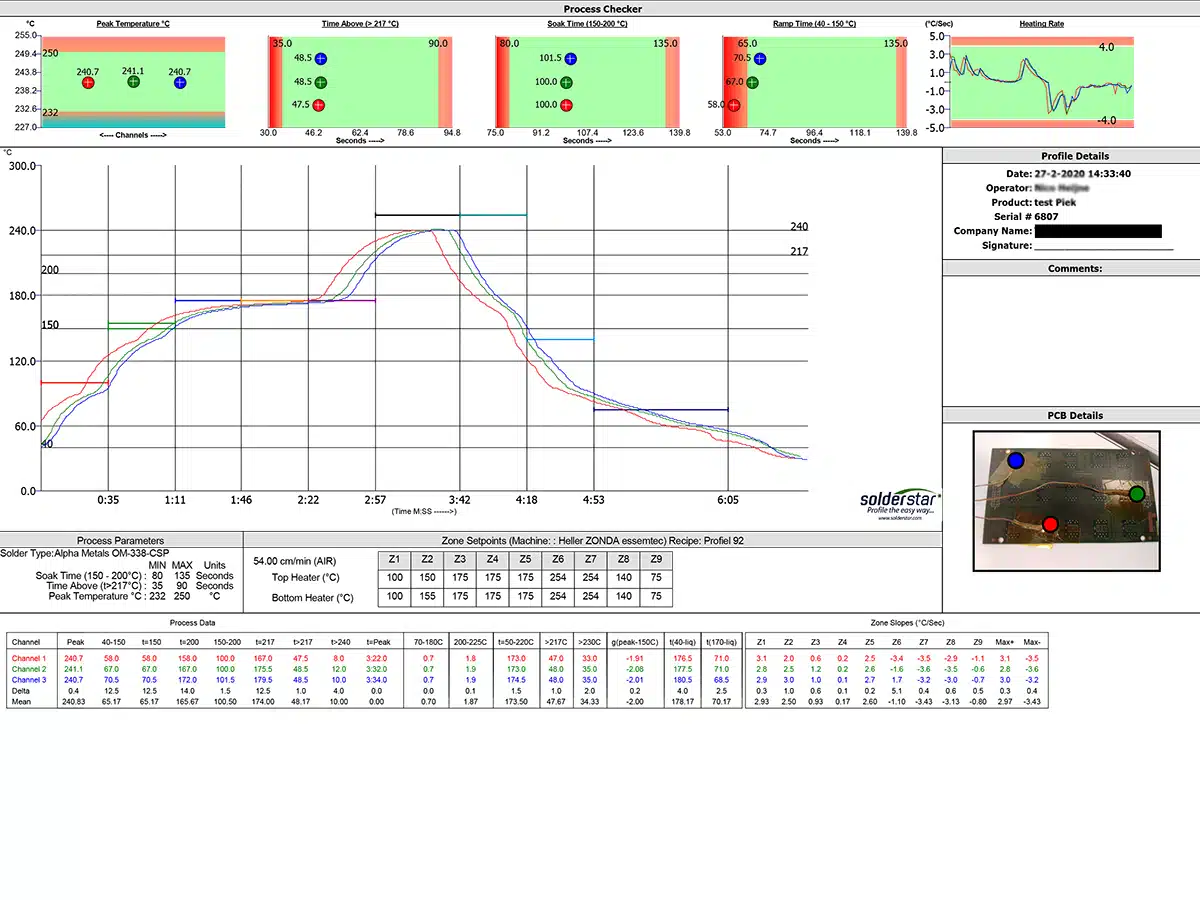

These defects can be avoided by checking the time-temperature-profile more often with the Smart Profiler SuperM.O.L.E.® Gold 2 or another temperature data logger. These data loggers measure the time-temperature profile of the soldering process.

With these measurements a lot of adjustments of the soldering process and solder paste can be checked and eventually readjusted. Thus, it is extremely useful for process control.

ECD’s Smartprofiler SuperM.O.L.E.® Gold 2 can measure a lot of parameters, e.g.: preheat temperature and time, soak temperature and time, reflow temperature and time, maximum component and PCB temperature and conveyor speed.

SuperM.O.L.E.® Gold 2 Thermal Profiler

In our training centre we use the Smart Profiler SuperM.O.L.E.® Gold 2 from ECD. The supplied software pack is splendid. You set the maximum deviation. Read the data from the logger into the software and immediately can see if the measurement was good or not. Even a deviant trend can be discovered quickly. Another advantage of this software is that it is possible to have a statistical process control (SPC) performed based on the measurements. This is mandatory for class 2 and 3 products according to the IPC J-STD-001 Requirements for Soldered Electrical and Electronic Assemblies Standard. More information on time-temperature profiles can be found in the IPC-7530A Guidelines for Temperature Profiling for Mass Soldering Processes (Reflow and Wave).

The moral of the story: Do not randomly change the adjustments of soldering process and see what the result of this action. Measure your process, thus you acquire data which you can use to avoid problems instead of solving them later (rework and repair). Furthermore, this data can also be used for process optimalisation and process control. This way you catch three birds with one stone.

Good luck with the time-temperature measurement with the smartprofiler SuperM.O.L.E.® Gold 2 from ECD or another data-logger. Measuring is knowing!