Articles and essays about the electronic interconnect industry often use the terms ‘rework’ and ‘repair’ as synonyms. Is this correct or are there differences in meaning?

This article will shed some light on this issue, and to do so PIEK has drawn up a list of short definitions.

Rework IPC-7711

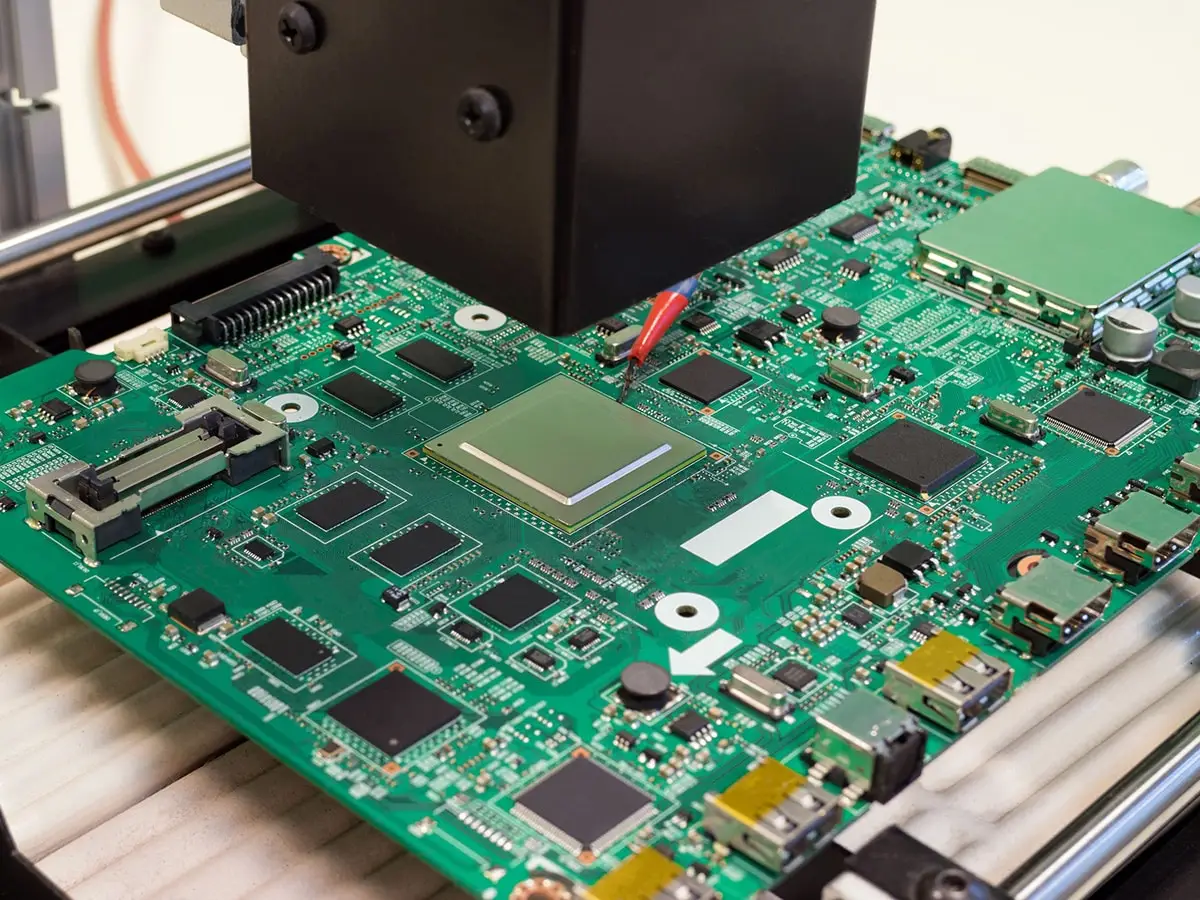

Rework refers to extra work that is needed on a component that does not meet certain criteria. Rework makes use of either the original or an alternative manufacturing process, provided that the assembly process at the end of the whole process completely meets the stated criteria. Some instances when rework is due: faulty soldering connections, missing components, incorrectly positioned components, wrong components, short circuits, etc.

The above definition of rework also implies checking whether the predefined criteria are met. The criteria have been clearly laid down for the electronic interconnect industry by IPC, the umbrella organisation for globally recognized standards in this industry. The guidelines in IPC-7711/7721 are the applicable criteria. This IPC standard clearly describes the steps to be taken by users and others who rework assemblies of printed circuit boards. The terms and definitions used are consistent and in accordance with the terminology of the other IPC documents used throughout the electronics industry.

The above definition of rework also implies checking whether the predefined criteria are met. The criteria have been clearly laid down for the electronic interconnect industry by IPC, the umbrella organisation for globally recognized standards in this industry. The guidelines in IPC-7711/7721 are the applicable criteria. This IPC standard clearly describes the steps to be taken by users and others who rework assemblies of printed circuit boards. The terms and definitions used are consistent and in accordance with the terminology of the other IPC documents used throughout the electronics industry.

Rework is often economically viable for a company able to rework faulty assemblies, beside the regular production, because it not only saves money but also raw materials. Apart from this, the environmental impact is positive. And finally, rework offers companies an opportunity to meet their warranty obligations.

Repair IPC-7721

Repair refers to restoring the functionality of a component that is not functional or that does not meet certain set criteria. Functionality is key here. Although the criteria will have to be met after repair, there may be cosmetic deviations, and/or the use may be slightly restricted. Examples are: broken or faulty tracks, loose pads, damaged passages, flaws in the basic material, etc.

The repair of assemblies also centres on restoring functionality. And the criteria laid down in the IPC-7711/7721 standard also have to be met, just as with rework. From an economic point of view a cost-benefit analysis has to be made before repairing components. More and more companies have now developed strategies for rework and repair. These strategies also include the IPC certifications for their own staff. This guarantees that activities are executed adequately and that products definitely retain their added value.