We can reflow solder Printed Circuit Boards Assemblies (PCBA’s) by using convection ovens, infrared ovens but also with the aid of vapor-phase ovens. We see them quite often at companies that build prototypes or produce a lot of different types of PCBA’s.

With vapor-phase soldering the condensing vapor from a boiling fluid is used to heat up the board (PCB), components and solder paste above the melting point of the reflow-temperature. This is the temperature just above the melting point of the solder paste.

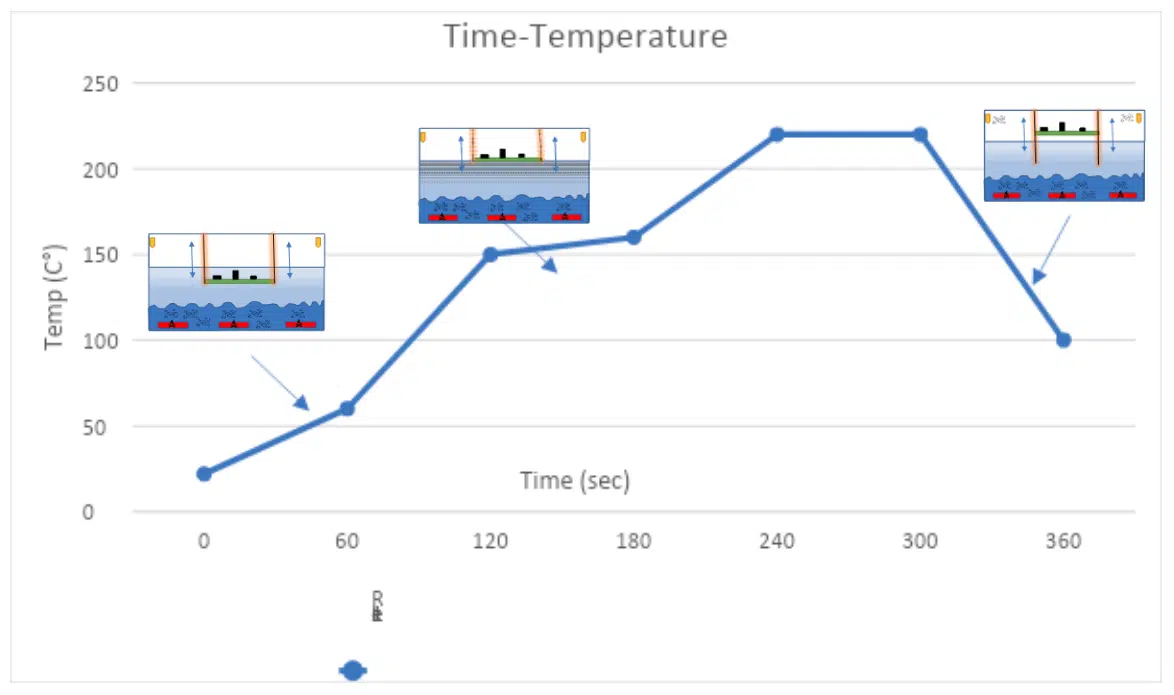

Vapor Phase temperature example leadfree

Basically, it works like this: the PCBA will be lowered into the vapor above the boiling fluid with an elevator system or a conveyor belt, where it will stay until Reflow is reached. After Reflow the PCBA will be removed from the vapor phase by the conveyor or elevator system after which the solder will solidify and the PCBA will cool down further. This final step might also be arranged with the controls of the heating element.

Vapor-phase soldering is used both for SMD and PTH (Plated Through Hole) applications. Originally it was developed to solder backplane-PCBA’s using solder preforms. De applied paste on the plated through hole often was insufficient to fill the entire through hole with solder. Thus, a solder preform is applied at the topside with the paste to achieve the correct solder quantity in order for the hole to fill completely and have the tin wet the component lead.

The big advantage of vapor-phase soldering is that you cannot overheat the components or PCB. The maximum temperature is the boiling point of the fluid used.

For leadfree soldering fluids have been developed with boiling points from 235C° till 250C°.

These fluids can be used for the usual leadfree alloys.

A disadvantage of the first vapor-phase machines was that there was not so much to control.

Depending on the mass of the lands on the PCB and the component terminations short and long soldering times were accounted (dwell-time). With the newer vapor-phase machines a control is possible, meaning that with these machines various time-temperature profiles (TTP) can be adjusted. The height of the PCBA can be adjusted in the vapor. In the illustration below you see an example of a soak profile. In some cases, vapor-phase soldering might have a lot of advantages compared to other reflow-methods.