Can you repair a bad crimp connection?

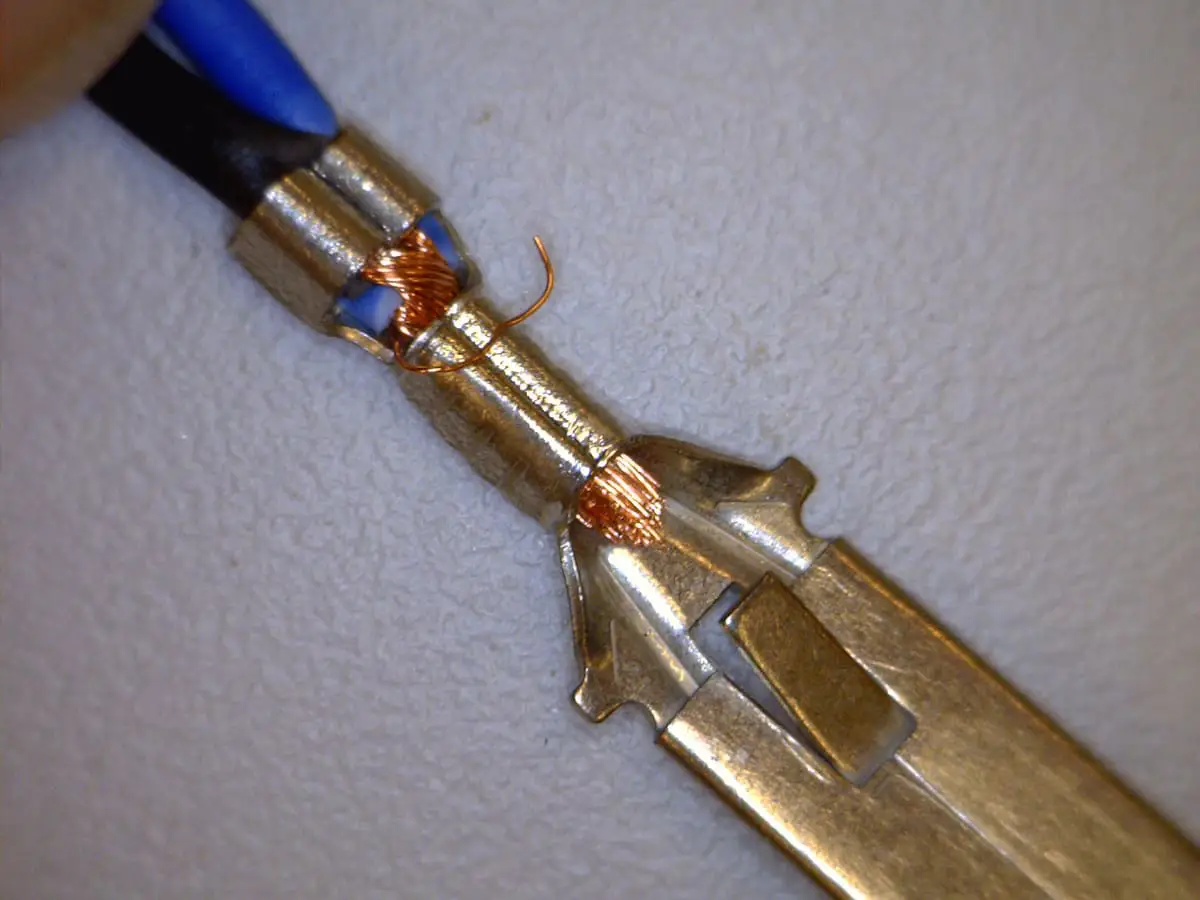

NO! The only way what you can do is to cut the old contact (provided there is enough wire length available), strip both the wires again and make sure that the wires are correctly and evenly inserted into the contact. Not as shown in the picture! This is an absolute defect for all product classes according to IPC/WHMA-A-620. The stripping length is incorrect, the wires are not evenly inserted so that the black wire does not have good insulation crimp. And the worst thing in this photo is that there is 1 strand outside of the electrical crimp which can cause a short circuit. In addition, the crimp bell mouth on the exit side is not sufficiently formed, which indicates an incorrect tool or adapter/or wrong size crimp contact is used. If there is no bell mouth on the exit side, a sharp edge will form at the brush end, causing strands to break off, resulting in a short circuit. The IPC/WHMA-A-620 standard provides comprehensive information on all types of crimp connections (open, closed, machined contacts, etc.), what is acceptable and what is not, with clear explanations, photos and text.