The electronic interconnect industry is continually innovating, and innovations obviously have a big impact on product quality. Newly created products make the lives of consumers safer, better and more pleasant, regardless of whether they are health-care products, in which technology, ICT, and knowledge are combined, or mobility products, in which technology, ICT and artificial intelligence come together.

In order to function properly and fulfill the expectations of consumers as well as the industry, it is most important that the electronic products go through several phases. These are shown above in the Circle of Quality. All steps in this circle contribute to the proper operation of electronic products and the satisfaction customers get from their use. Sometimes even people’s lives depend on the reliable functioning of these products. Would you board an aircraft if you would know that the engine controls were not operating properly?

It all starts with the PCB Design. A designer considers all operational requirements and translates them into schematics, drawings and other documents necessary for the later process steps. Next bare boards (or printed circuit boards) are manufactured at the PCB Fabrication stage. These bare boards will later carry the electronic components that make the functioning of the electronic products possible. This step we call PCB Assembly.

In another process (often a different factory) the cable and wire harness are made, also in line with the instructions set out by the designer. When all elements have been produced the final product is then assembled into the housing that was designed for it. PCBA (printed circuit board assembly) and wire harness are “married”, the product is ready for its final application.

At the production stages, errors can occur that render the elements useless for the end product. Instead of just scrapping the affected PCB’s, PCBA’s or wire harnesses often these are reworked or repaired, saving on production costs and waste material.

IPC, the global operating trade association, publishes a vast amount of regulations and standards in cooperation with the technical interconnect industry on all the subjects mentioned above.

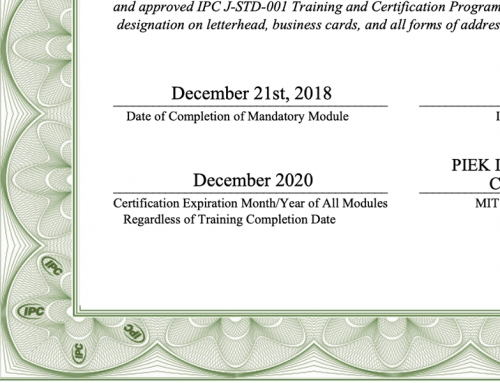

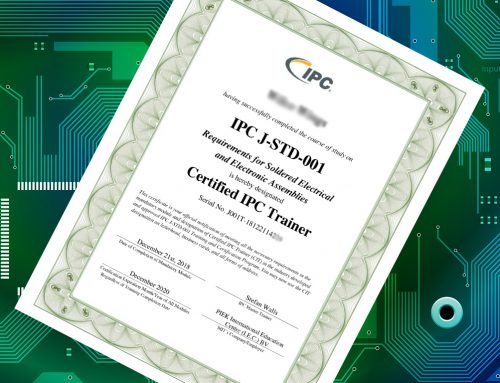

One of the performance specifications describing materials, processes, and tests for the PCB manufacturer is the IPC-6012 standard. Acceptance criteria for the printed circuit board (PCB) are found in the IPC-A-600. To assure the quality of the assembly stage extensive process information is gathered in IPC-J-Std-001. This document describes the materials and equipment that is to be used for the assembly of the electronic products. Before the electronic assemblies leave the assembly area in many cases they are inspected according to the IPC-A-610 standard.

For the wire harness production process information and the acceptance criteria are described in the IPC/WHMA-A-620 standard. Finally, for most (if not all) rework, repair and modification operations the proper procedures are well described in IPC-7711 and IPC 7721.

PIEK is the organization of choice for all training and certification courses related to these IPC standards. We are one of the few training institutes worldwide that can offer all momentary available IPC certifications, even in several languages. All our Master Trainers have decades of IPC and general training experience and are specialists in their field.

But PIEK offers more. To serve the electronics industry and its needs PIEK has developed its own PIEK courses on various subjects, sometimes even not covered by IPC. With the full liberty of development and the knowledge and experience of our trainers in these training courses, we can even go a step further and offer our customers an in-depth approach and practice related solutions. Participants (and their employers) profit from the extra “baggage” provided that can make all the difference in the market. Furthermore, these PIEK training courses are customizablemisable to the specific needs of our customers.

PIEK is uniquely positioned to provide all possible services to you. If you are interested in an IPC certification training or a PIEK training, please contact Mrs. Wendy Wings at our customer care department. She is available on telephone number + 31 45 570 33 33.