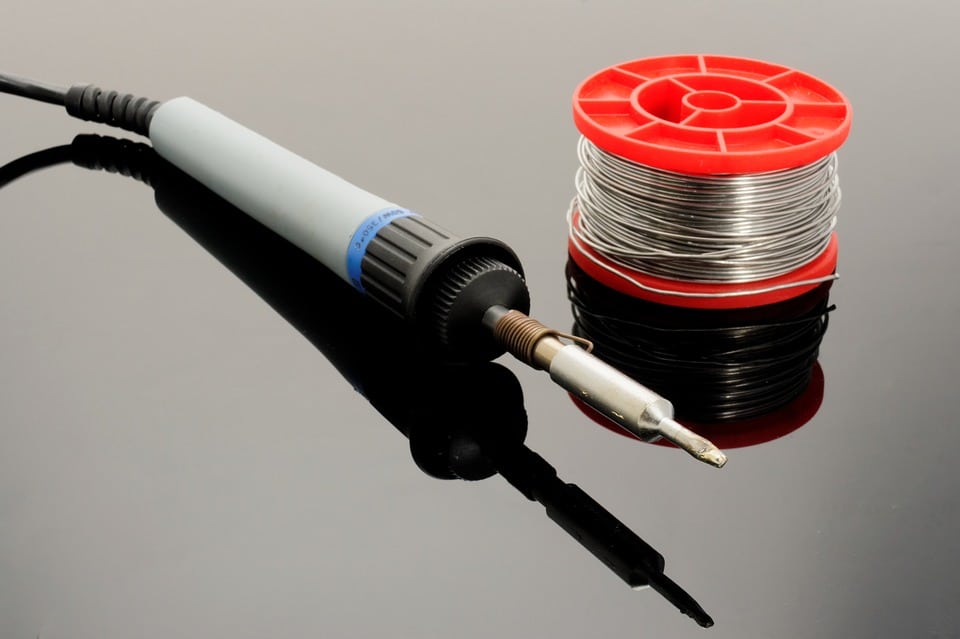

Last year, Piek showed the basics of hand soldering, and today we’re taking things to a more fundamental level. We’ll be talking about the right tools you’re going to need and how to choose them, as well as the proper care and maintenance.

Choosing a soldering iron

Before purchasing your first soldering iron, you need to consider the type of iron, temperature, and wattage. The type of iron and temperature you’ll need are dictated by your project.

The soldering pencil is the most basic and inexpensive and it’s limited to low-powered projects because it lacks temperature control. Hunker notes that it’s suited for working with electronics and circuit boards because of the small tip.

Meanwhile, soldering guns may or may not come with temperature control, but they have a built-in transformer that can convert power to a lower voltage. This allows them to heat up faster than soldering pencils. However, this also comes at a disadvantage because they can generate too much heat and are recommended for high-powered projects.

Finally, there are soldering stations, the most sophisticated and costly of the three types. If you need to be precise about heat, a soldering station is your best bet as it’s typically fitted with a bench top control for getting the right temperature you need. Soldering stations have the widest range of uses.

The third point of consideration is wattage. Irons typically have a rating of 15 to 25 watts. Heavy-duty projects require a soldering iron with a higher wattage as it contains more power on reserve. This means that it’s able to heat for longer periods than lower-rated irons. Soldering Gun Guide notes that a 15-watt iron is enough for working with electronics as it also avoids overheating the circuit, while bigger DIY projects may require a 25-watt iron.

Caring for your iron

As tools go, soldering equipment may be relatively inexpensive but they can still last a long time with proper care. First, always make sure that the iron is unplugged and not heated when cleaning. To clean the tip, use a sponge or sandpaper to scrub the debris off. If you’re having a hard time restoring its lustre, you can use a tip cleaner made with rosin flux which will remove the residue off and add a shiny new coat. Thankfully, most soldering irons come with interchangeable tips. If your current tip can no longer be salvaged, you can purchase a new tip without having to buy a new iron.

Application

Whether you realise it or not, soldering is a huge part of modern life. Plumbing systems in our homes cannot be constructed without soldering copper pipe joints. Outside the house, soldering plays a huge role in fields like auto repair especially in filling small cavities under the hood.

Most of the items we use on a day-to-day basis have also underwent soldering in one way or another. Some artists, from jewellery makers to sculptors, have had to dabble with the trade to produce sturdy pieces. It is also an indispensable skill in the electronics industry, particularly in creating and repairing circuits found in everyday devices like gadgets and appliances. They pave the way for transferring information, or what’s known as telematics. Verizon Connect explains that this branch of information technology is concerned with processing and communicating information with devices that are connected to the cloud. For instance, sensors and tracking devices are basically mini-computers. Mobile data is also a prime example of telematics, which people use to connect to virtually anyone in the world.

Some people might think that soldering is an impractical skill, but without it, the components needed to build these objects would not have existed. So choose your weapon wisely and start building!

Content intended only for the use of piektraining.com

by Emily Kimble