Tales of introductory soldering are a mix of excitement, fear, and sometimes failure. However, first soldering efforts don’t always need to be daunting or a risk to the success of your project. Although soldering expertise will take many levels of practice (IPC training, IPC certification, experimentation, and surface mount experience), there is no reason why your initial venture into soldering has to adversely affect the success of your project. There is certainly a high variability in difficulty for soldering projects, but working on the basics will have you soldering like a pick-and-place machine in no time*! (*Disclaimer: Maybe not, but we can all dream.)

Working on the basics will have you soldering like a pick-and-place machine in no time*!

Step 0: BREATH!

Unfortunately, it does not always go without saying, but soldering safety procedure review is the first “best practice” tip for any level of hand soldering. Proper ventilation is often overlooked, but soldering fumes are potentially hazardous, so it is best to start early with safe practices.

Step 1: Learn the differences.

Any electronics veteran will tell you a few things: ESD (Electrostatic Discharge) is not just a scare tactic, the concept of “common ground” is a misconception, and all soldering equipment is not the same. When selecting a solder station, understand the differences in composition before you buy (i.e. are you buying lead-free? Expect a high melting point). In addition to the solder station itself, there are more differences to understand in soldering tip selection, temperature selection, flux selection, and technique.

Step 2: Start small. Or actually… large!

If you are learning to hand solder for the first time, starting with a high density, surface-mount technology device with strict signal integrity requirements is like trying to program an FPGA with experience in journalism: it won’t work. To get started, through-hole soldering is the best place for initial experience. Work on perfecting joints before overstepping your ability.

Step 3: Practice makes perfect you better.

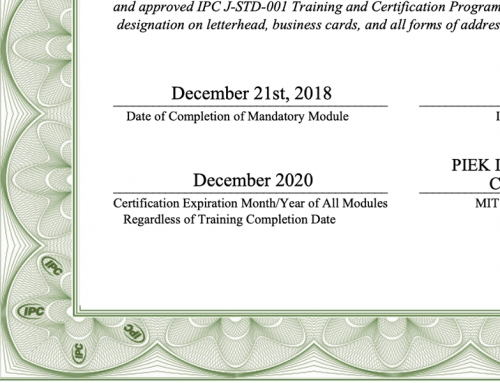

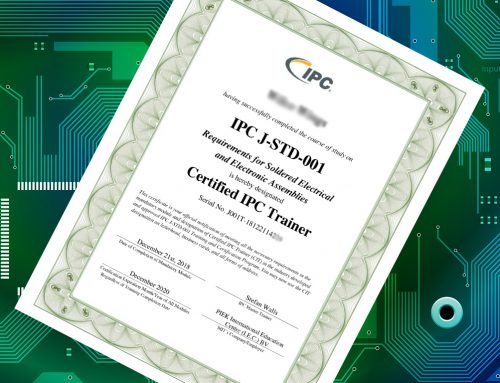

Have a project that requires specific soldering of a part you have never used before? There is no reason to experiment for the first time on an expensive component that you might damage with lack of experience. There are professional solder training programs available such as IPC-7711/7721 Training and IPC J-STD-001 Training. Said training programs allow you to practice hand soldering on different package types with less pressure than working on the real thing. You can even practice removing the component as well. Inspect your work with a microscope in between joints and at the end to ensure there are no mistaken connections causing shorts.

BONUS: Clean your tip.

Get a good soldering tip cleaning sponge and preserve the lifespan of your soldering iron with frequent cleanings.