The term “electrostatic discharge” (known more commonly as ‘ESD’) simultaneously strikes fear and disdain in the hearts of electronics engineers. The thought that some do not use proper precaution in dealing with sensitive electronics —or even worse, do not BELIEVE in the damage potentially caused by ESD— can put a project in danger. So, please, PRACTICE SAFE ELECTRONICS. Here’s how!

What is ESD?

To put it simply, you are a danger to electronics without protection. There is an abundance of material available to teach you the what exactly electrostatic discharge is and how it can be represented by the human body model (HBM) or the charged device model (CDM). For now, it is important to know that the human body accumulates charge from a variety of sources and can discharge through contact to cause damage in a sensitive device. Ever slide your feet on the floor and shocked a friend?

Know Your Classification

Device sensitivity (or ESD susceptibility) is classified by levels to quantify the dangers of ESD. It is important to understand and study the range of ESD sensitivity classification. The classifications in the HBM range from Class 0 to Class 3B. Typically, hobby electronics will not deal with Class 0 parts (which usually require active ESD monitors, grounding floor pads, and ESD protective jackets). Before undertaking work on a project, find out the highest component classification in the bill of materials (BOM) and perform all work at that level.

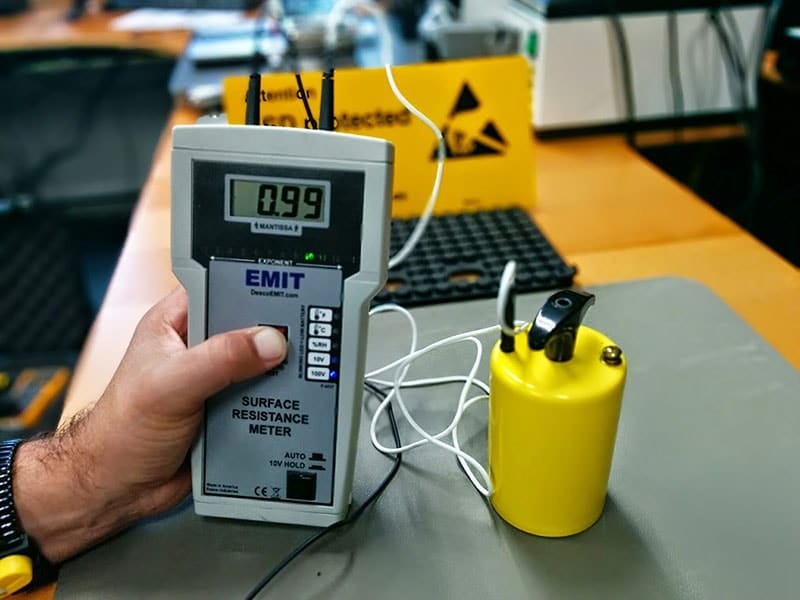

Learn to Mitigate Electrostatic Effects

The most common solution to mitigate the effects of ESD and prevent potential damage are available from specialist suppliers in ESD materials. At the minimum, considering a grounding mat and anti-static wrist strap. Many wrist straps include an alligator clip at the end. This feature allows the user to ground to a common ground in the system, such as a computer chassis when building a PC. As classification on parts increases, proper ESD training can make all the difference in the success of a project. There is no reason a project should be at risk if ESD classification and damage mitigation are given appropriate consideration. Aside from damaging and needing a replacement component, the work required to debug an issue caused by ESD damage is completely avoidable.

–

ESD is often seen as either a fairy tale or boogeyman, depending on who you ask. Although it is easy to plead ignorance on the topic, proper ESD training and handling of components are a necessary practice for all engineers and technicians. What do you have to lose?

Oh yeah, a very expensive Class 0 component…