Would you like to learn how to solder wires to different types of “terminals” (contacts)?

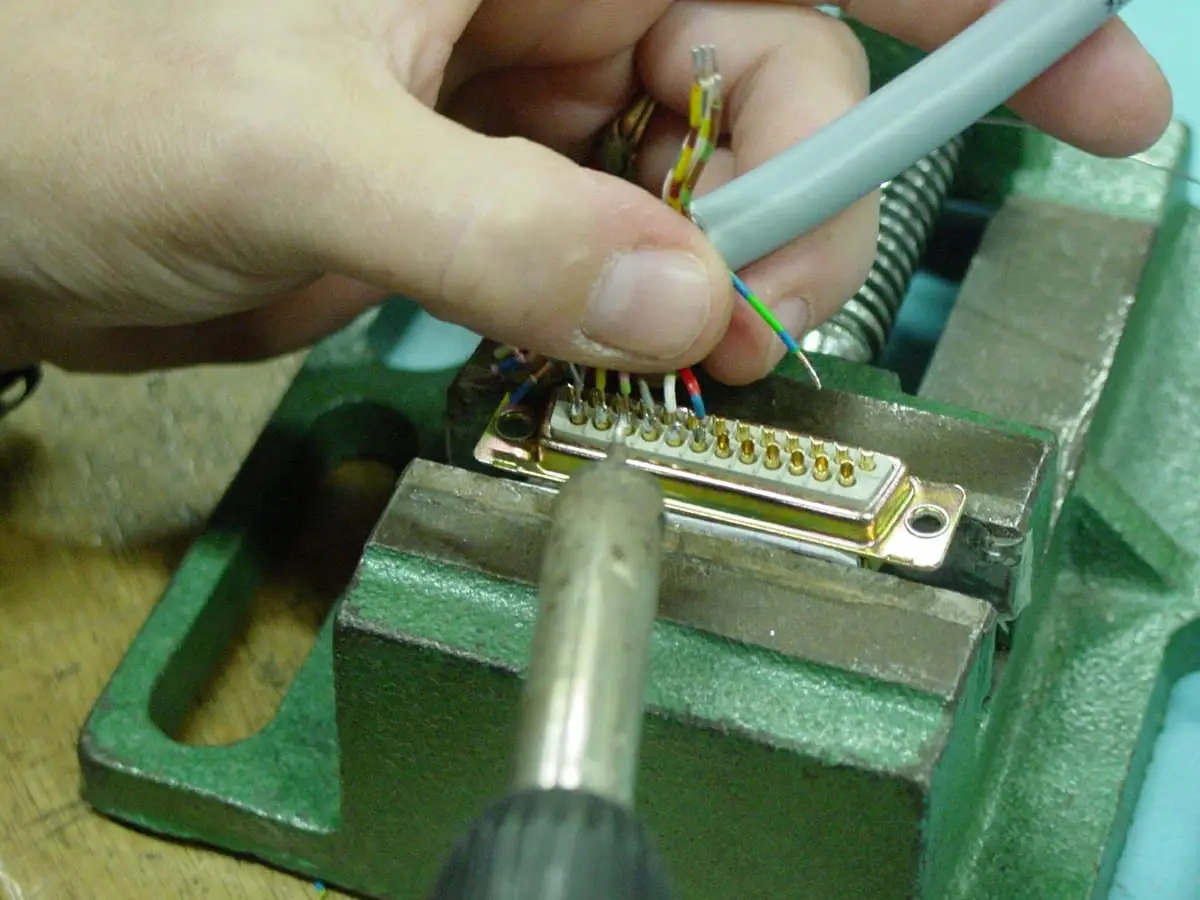

PIEK has developed a practical course in which the different types of terminals are discussed, how to swage/mount terminals into the printed circuit board, how to solder terminals and where you can find the different types of terminals in electronic products. You will also learn how to strip wires, what’s the maximum conductor damage, pre-tinning wires and the minimum wire wrap to guarantee a reliable electrical and mechanical solder connection to the different types of terminals. Terminals are sometimes vital, depending in which product they are used and what application they have. Which 3 IPC standards can be used to inspect terminals? This will be discussed, also the 3 end product classes, so everyone knows what is acceptable and what is a defect condition. The practical part will be performed with professional soldering stations from e.g. Weller, JBC, Metcal, OKi, Hakko, Pace or Ersa. The goal of this training is to educate beginners as well as advanced participants all the specific “tips and tricks” and knowledge needed to guarantee that the end products will function with a long life time. Also important is that the participant learns how to maintain their soldering equipment, soldering tips are becoming more and more expensive and poor maintenance can drastically reduce the life time of the tip, which increases company costs. Everything from the basics to the end will be discussed. What is AWG, what types of wire insulation are available, stripping (3 methods), what type of soldering tip is the best choice for what each type of terminal, how to clean the soldering tips, which temperature is best for soldering, thermal mass, intermetallic layer etc. Using professional PowerPoint presentations and instructional videos, this training will be a very pleasant learning experience for you.