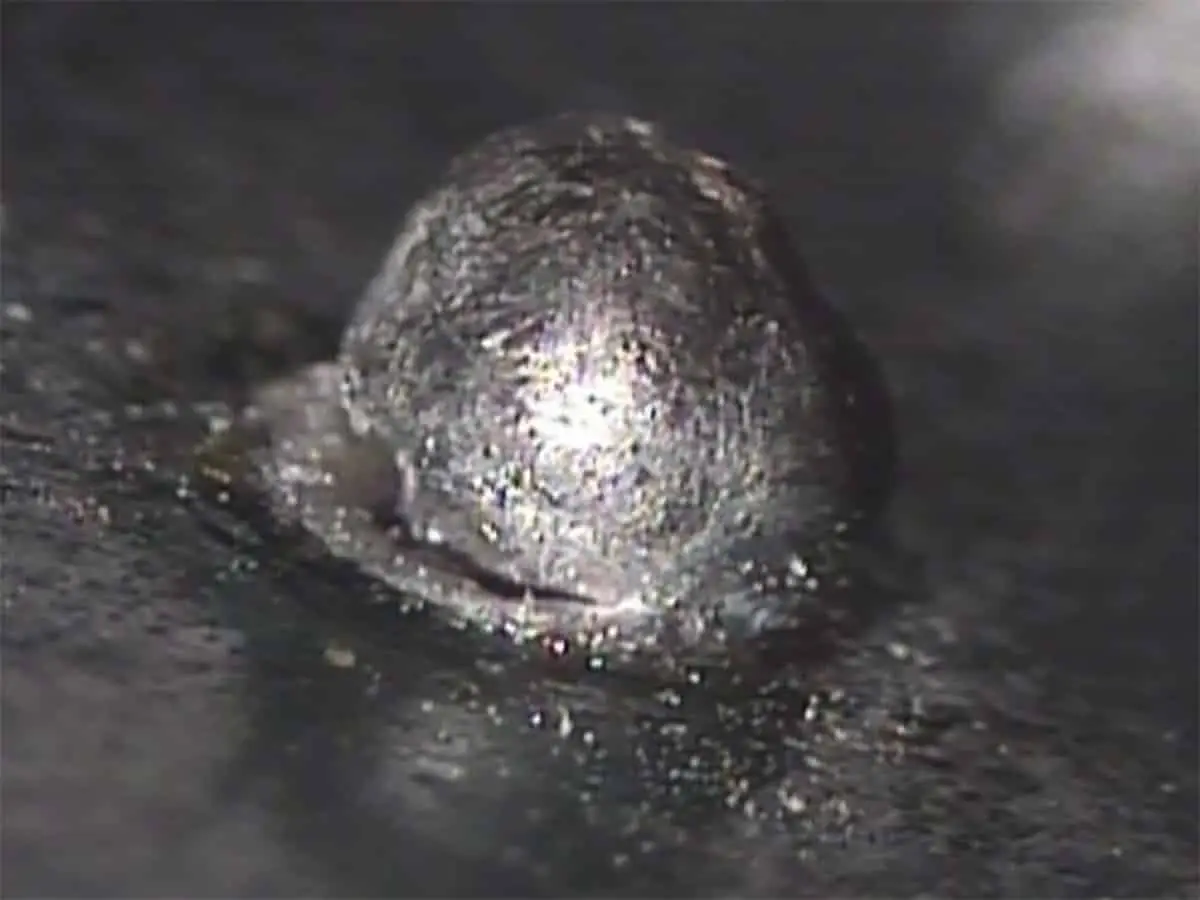

The picture shows a cold solder joint. This is a defect for all product classes as described in IPC-A-610, J-STD-001, etc. The cause of this problem could be:

- Dirty/oxidized soldering tip

- Too little/no flux

- Incorrect soldering temperature

- Soldered too quickly by hand/machine

- Dirty/oxidized surface of printed circuit board

- Dirty/oxidized component lead/termination

- Thermal mass (too small soldering tip or too much thermal mass in printed circuit board)

- Wrong technique (no heat bridge)

A good solder connection is created by the right combination of time and temperature. If one of the above problems occurs, either the time or the temperature will not be enough causing poor wetting and a cold solder joint as a result. It is important that the soldering tip is cleaned properly, that you use the correct amount of solder and flux, set the correct temperature, use the correct method as indicated in the IPC-7711/7721 and/or J-STD-001 and of course that the surface that should be soldered is properly cleaned before you start the soldering operation.