QFN components are part of the BTC (= Bottom Termination Component) style components. They have their connections only at the bottom of the package. QFN is the abbreviation of Quad Flat No Lead, meaning it is a component without leads and I/O connections on four sides (well actually only at the bottom of each side). It is one of the component types described in detail in the IPC-7093 document.

QFN components are part of the BTC (= Bottom Termination Component) style components. They have their connections only at the bottom of the package. QFN is the abbreviation of Quad Flat No Lead, meaning it is a component without leads and I/O connections on four sides (well actually only at the bottom of each side). It is one of the component types described in detail in the IPC-7093 document.

The advantage of these types of components lies in the fact that they occupy only little space on the circuit board. With miniaturization in mind this obviously is a good thing. If components are smaller you either can put more functionality on the same area or make products smaller all in all. We all want cell phones that are small enough to fit in a pocket but have functionalities that outrun business computers of a couple of years ago.

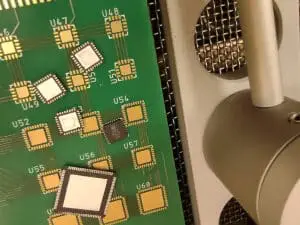

But somehow the price for all this is paid. And in the case of the QFN components, they come with some disadvantages and issues. One of them is inspectability. With the connections at the bottom visual inspection is almost impossible. Even when with some types the terminal is partly visible at the periphery, this surface area in general is not solderable, due to the fact that they show unprotected copper, because of their manufacturing processes. Hence the problems with solderability. In most cases the only reliable area to obtain a well soldered connection is the bottom side of the terminal, which is invisible for the inspector’s eye.

Then there is the issue of the thermal pads which we find on many QFN housings. Impossible to inspect visually their solder connections also tend to show voids, which will only be detectable by X-Ray inspection.

Then there is the issue of the thermal pads which we find on many QFN housings. Impossible to inspect visually their solder connections also tend to show voids, which will only be detectable by X-Ray inspection.

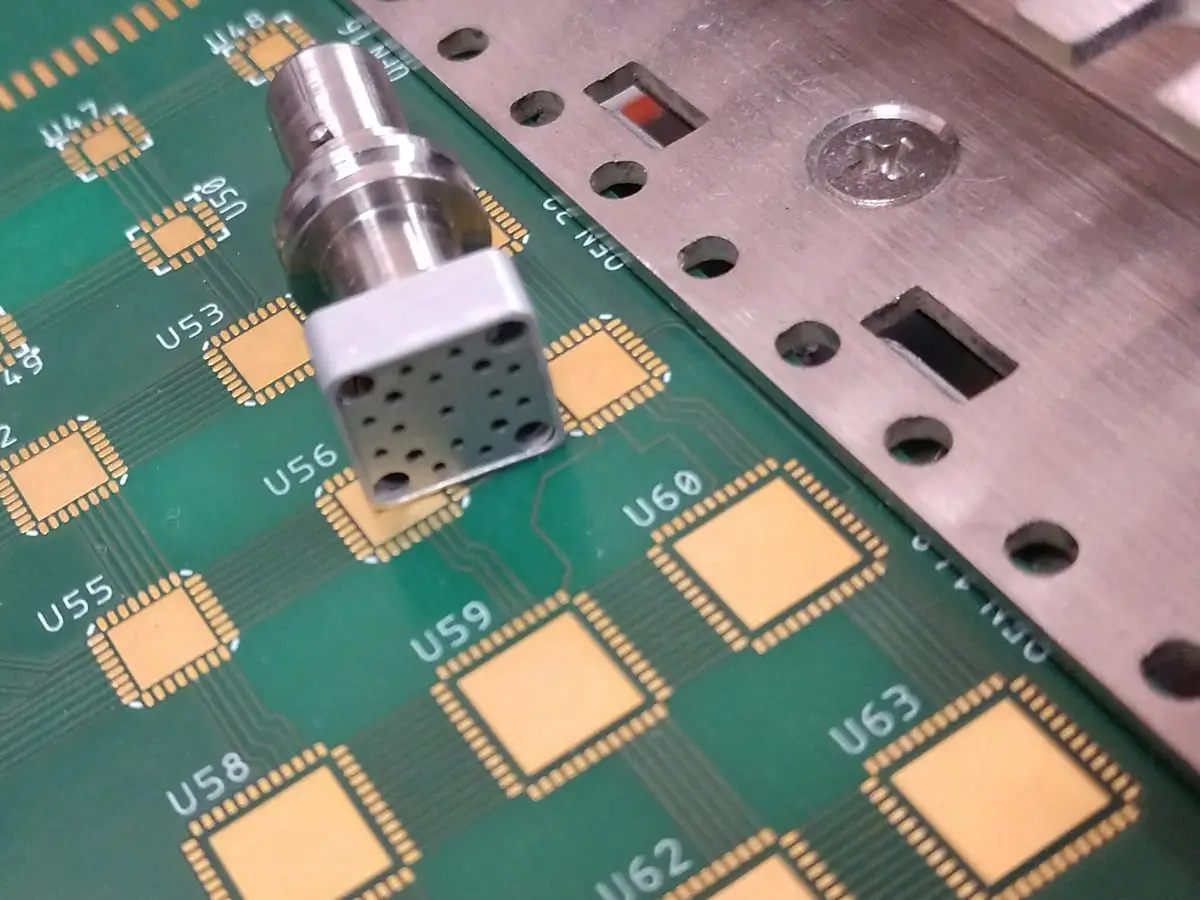

In a production area proper setup of the process together with process control will at least somehow assure that the QFN’s are properly installed and soldered. But what if they must be reworked, e.g., a component must be exchanged, for reasons of misalignment or others. If you have access to a dedicated, sophisticated rework station at least you have the luxury of working with fixed Time-Temperature profiles. And thus, can maintain some form of process control.

But sometimes workshops do not have access to these types of equipment. And then components are exchanged using commonly available hand tools and techniques. Apart from the issues with inspection (or rather the impossibility of it) they then also face the issues of a lack of proper process control. It all comes down to proper tools and especially craftmanship of the operator. Things he can only gain from a proper training and experience.